Differential lock switch

Safe control in series.

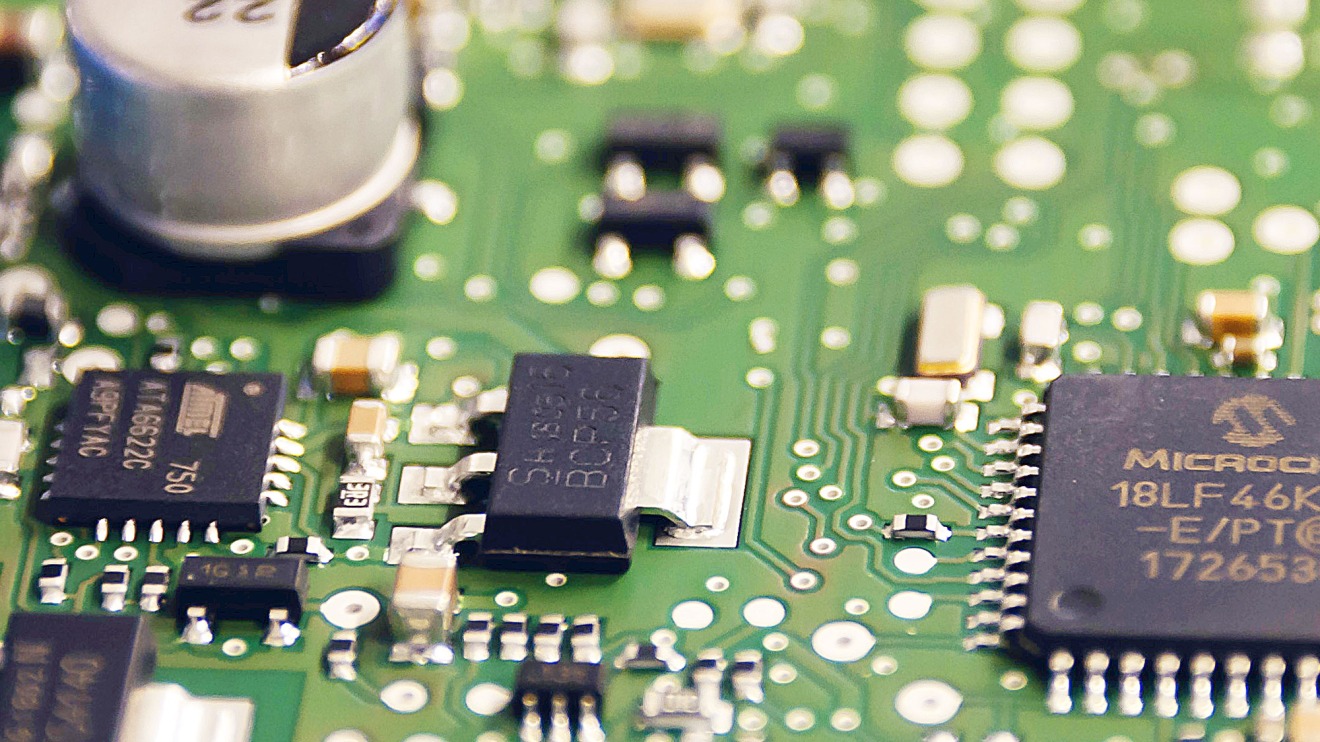

The differential lock switch is installed as standard in the dashboard. It is a centrally visible control element and enables the user to control the vehicle's three differential locks. But there is much more behind the switch's three easy-to-use buttons. A complex control unit with AUTOSAR operating system and 32-bit processor is concealed in the fibreglass-reinforced plastic housing. Connection to both the vehicle's CAN and LIN interfaces has been ensured. To prevent incorrect operation, we have developed the system in accordance with functional safety requirements in line with ISO standard 26262, ASIL level B, and are now manufacturing it in series production at our company with the same high standards.

experience and competence.

More then 30 years of development and production.

Intelligent, high-quality designed products.

Contact us

You pose the question, we provide the solution.

Write us using the contact form below or by email.

Project enquiries

The top of the state of the art.

We look for your clever solution. Functional, safe and reliable.

Realization at the highest level.

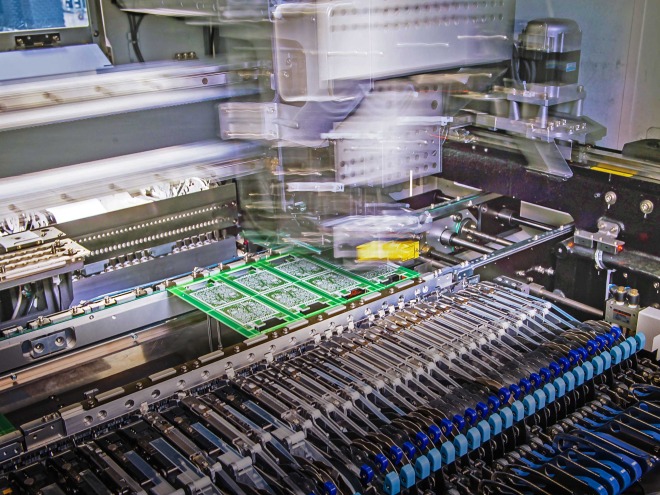

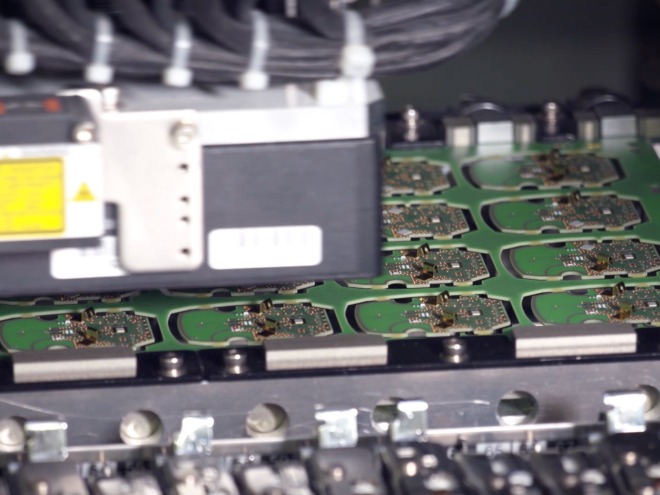

We work according to the latest standards. IATF, IPC, ISO, FUSI ... - from prototype to series.