SMD

SMD competence in series.

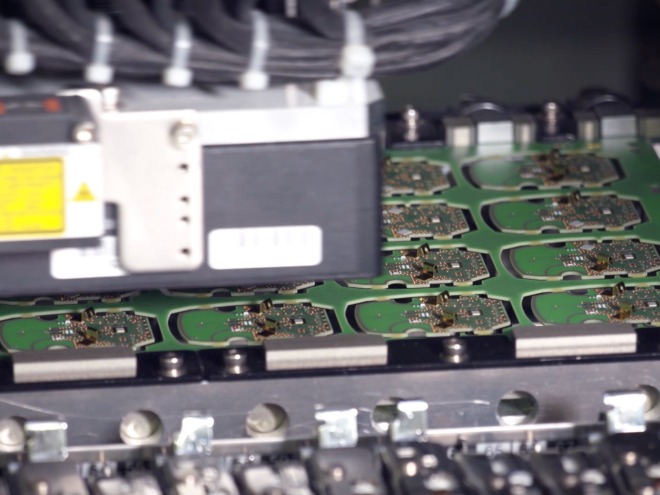

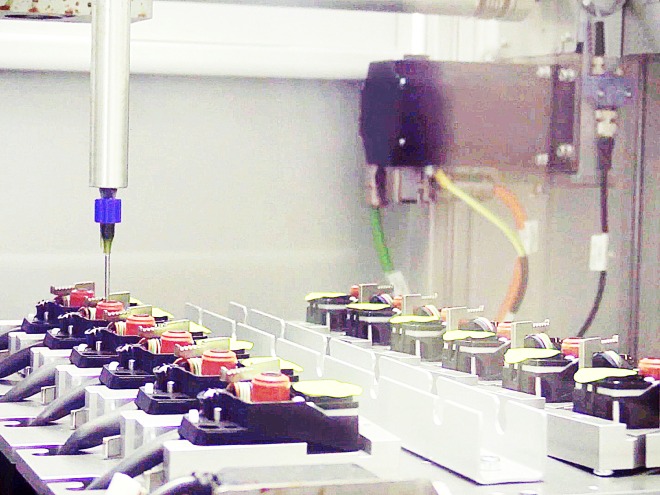

On several high-performance SMT lines, we assemble fully automatically rigid and flexible printed circuit boards with all common SMD component shapes up to a component size of 0201. We produce samples or small series, series in the middle segment as well as large series. Our SMT production (Surface Mounted Technology) stands for proven precision in execution, short production times and enables the series processing of particularly small components. All necessary component shapes, such as capacitors, resistors or microcontrollers, are placed quickly and in large numbers on the circuit board and then soldered by reflow process.

Our Mission

In our actions, we constantly question ourselves to find clever solutions for access and connectivity, HMI controls and electronic control units to make peoples‘ lifes easier, more comfortable and secure.

(Managing Director Dr.-Ing. Sascha Berger)

Contact us

You pose the question, we provide the solution.

Write us using the contact form below or by email.

Project enquiries

Realization at the highest level.

We work according to the latest standards. IATF, IPC, ISO, FUSI ... - from prototype to series.