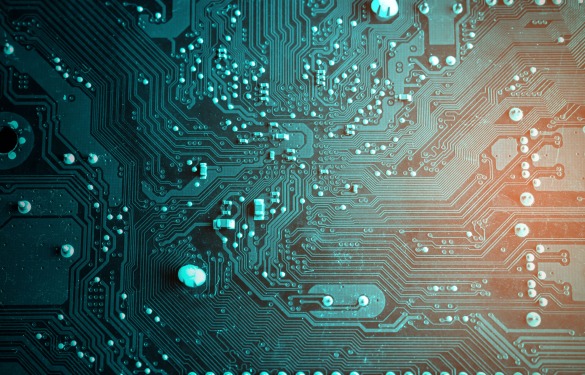

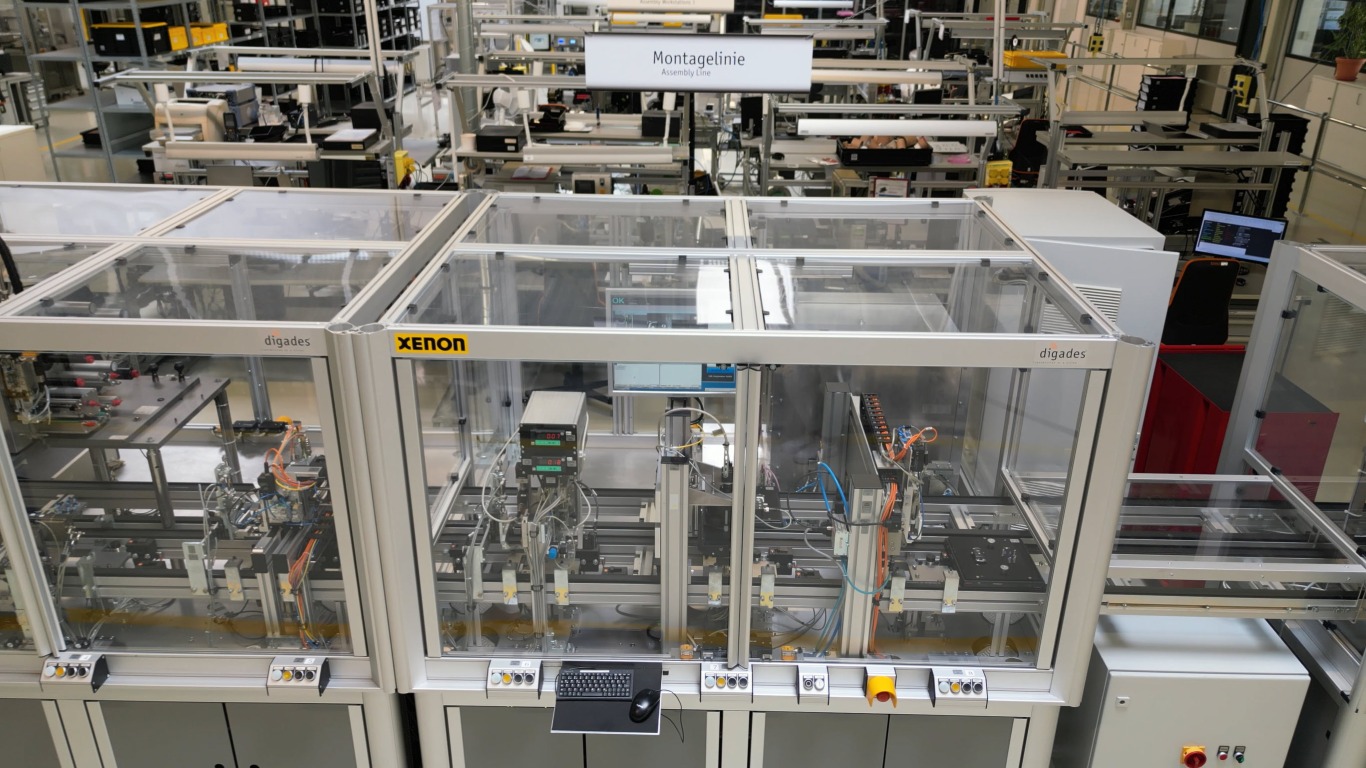

We keep an eye on your production. Every year, we manufacture around 1.2 million assemblies to the highest standards - and can scale up at short notice if required. Our production center offers state-of-the-art technologies and processes to manufacture your electronic assemblies precisely, economically and efficiently.

Flexible from the idea to series production

Whether manual assembly or fully automated production - we adapt our processes to your product. Thanks to Design for Manufacturing, we optimize at an early stage for time-saving and cost-efficient production. With our near-series sample production and sophisticated assembly concepts, we are flexible enough to react quickly to changes.

Quality that sets standards

- Control units & electronic assemblies to the highest standards

- ISO 26262-compliant production for functional safety

- ESD-compliant production & 100% traceability

- Effiziente Prozesse mit kurzen Wegen zwischen Entwicklung & Fertigung

Made in Germany – with maximum precision and reliability.

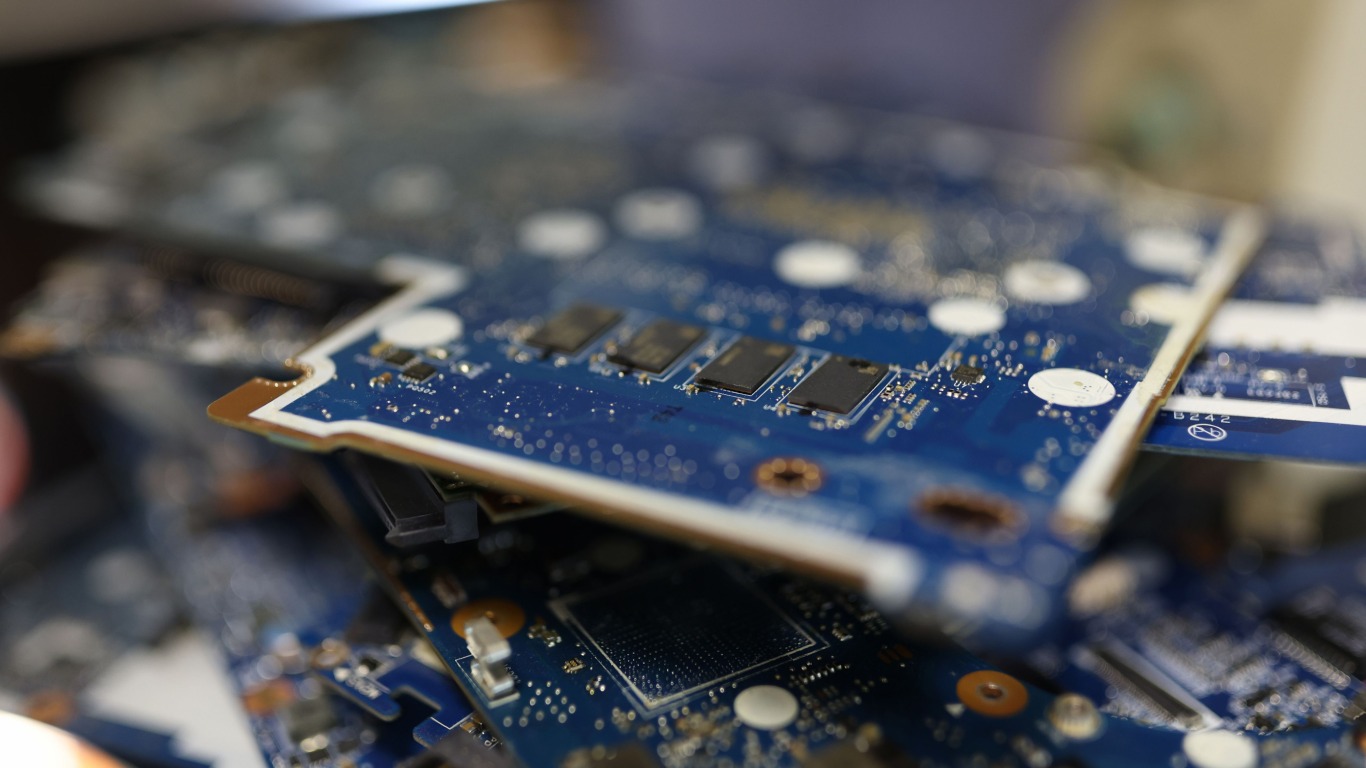

High-quality & complex electronic assemblies

Complex requirements, clear results: high-quality assemblies with a high level of vertical integration and series stability

Mehr erfahren

From sample to mass production

Design. Pattern. Series. One workflow, consistently high quality

Mehr erfahren

Quality and process reliability

Made in Germany - precisely manufactured, audit-proof documentation. From FMEA to end-of-line: tested quality with clear evidence.

Mehr erfahren

Logistic

Predictable short delivery times: Forecast-supported with safety stocks and flexible delivery windows

Mehr erfahren

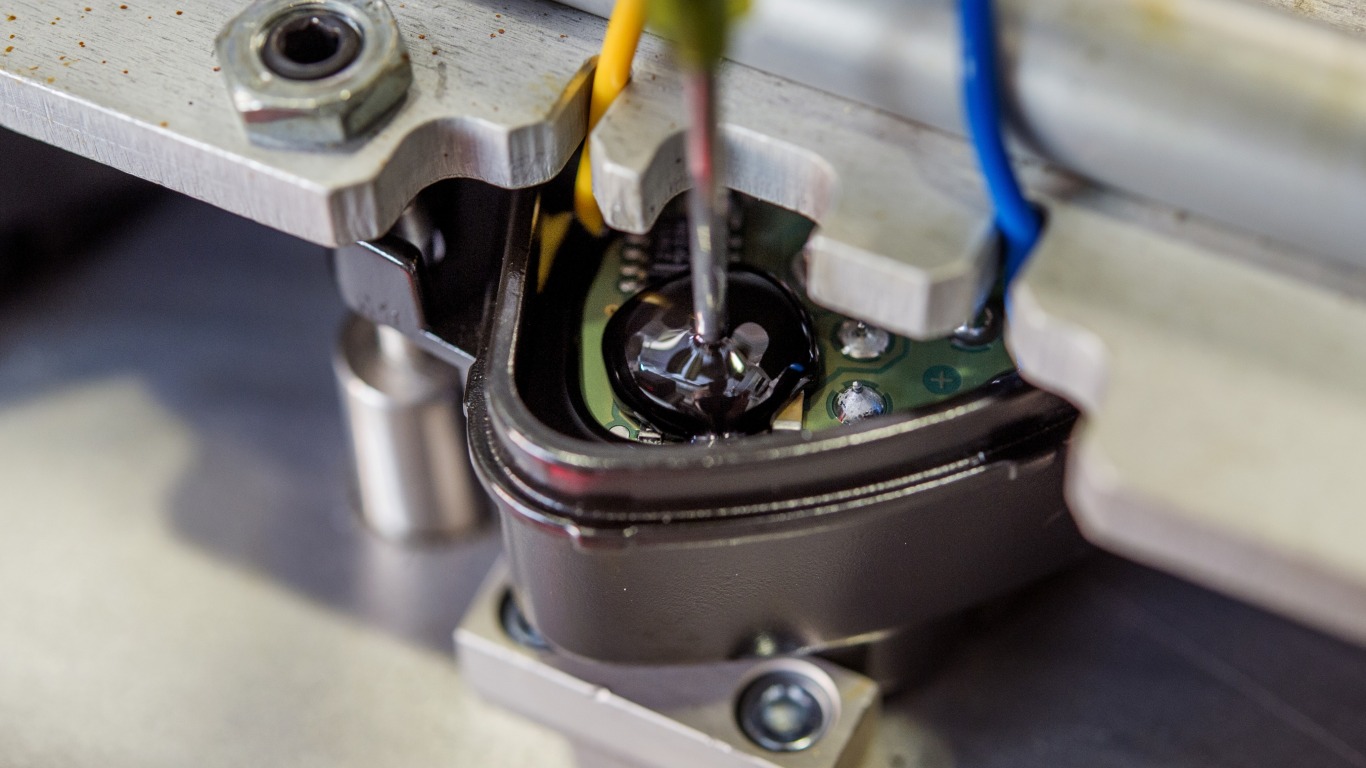

Synthetic resin casting process

Sealed against corrosion: our synthetic resin encapsulation technology.

Mehr erfahren