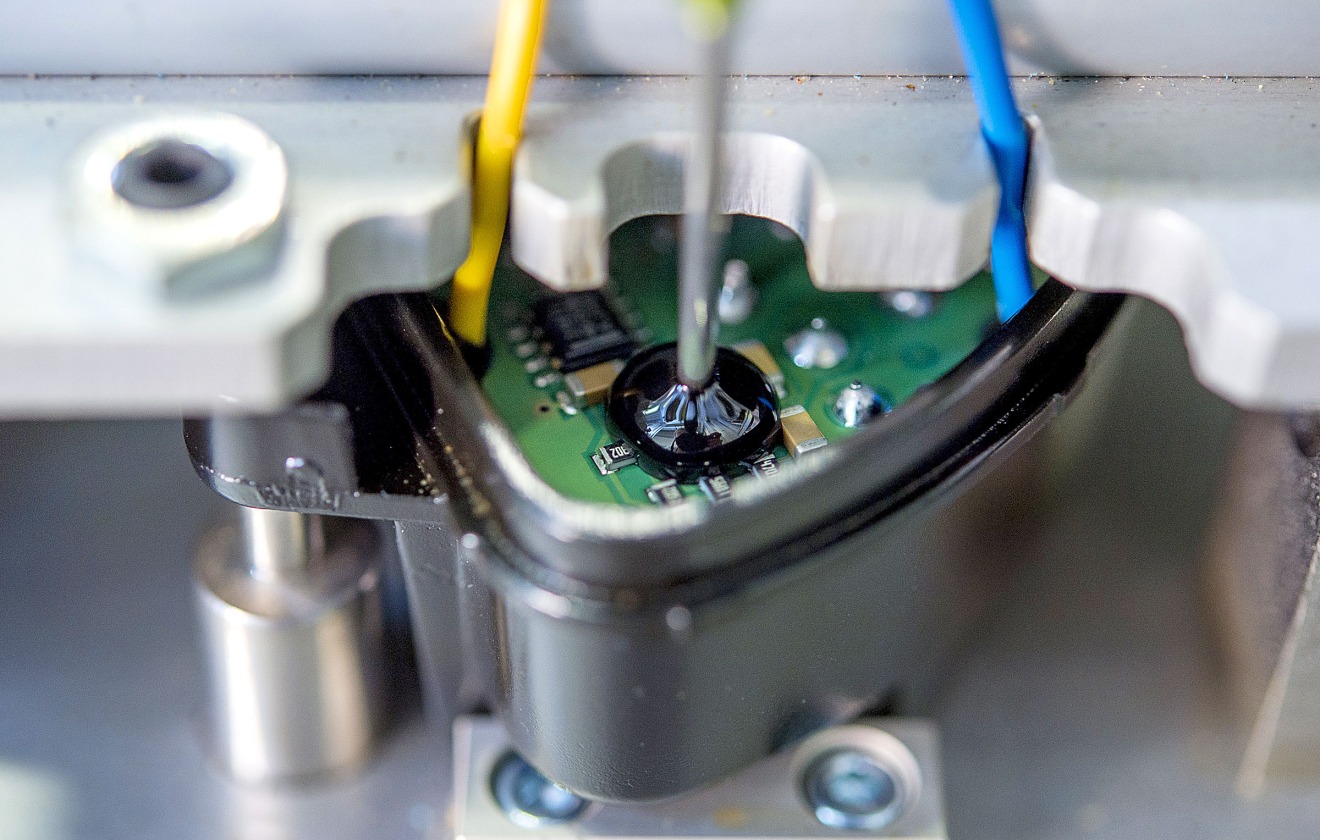

Synthetic resin casting process

Sustainable protection for the highest requirements.

Our special synthetic resin casting technology insulates and prevents the penetration of substances leading to corrosion. Electronic components are effectively protected against moisture, chemical as well as mechanical and thermal environmental influences. Surface sealed and, if desired, certifiable according to protection standard IP67.

Our Mission

In our actions, we constantly question ourselves to find clever solutions for access and connectivity, HMI controls and electronic control units to make peoples‘ lifes easier, more comfortable and secure.

(Managing Director Dr.-Ing. Sascha Berger)

Contact us

You pose the question, we provide the solution.

Write us using the contact form below or by email.

Project enquiries

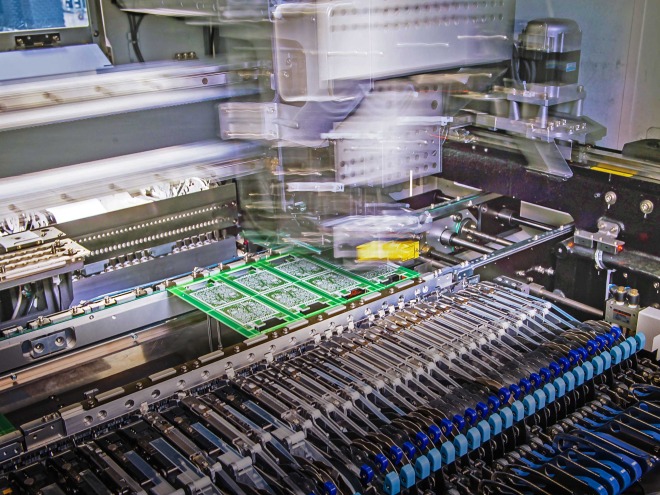

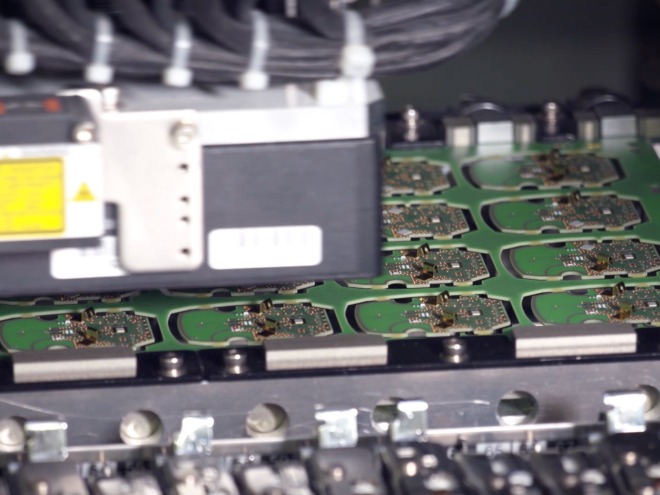

Realization at the highest level.

We work according to the latest standards. IATF, IPC, ISO, FUSI ... - from prototype to series.