Validation

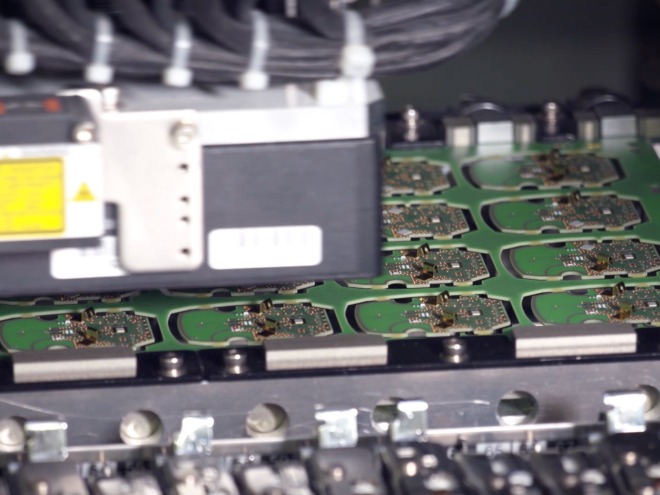

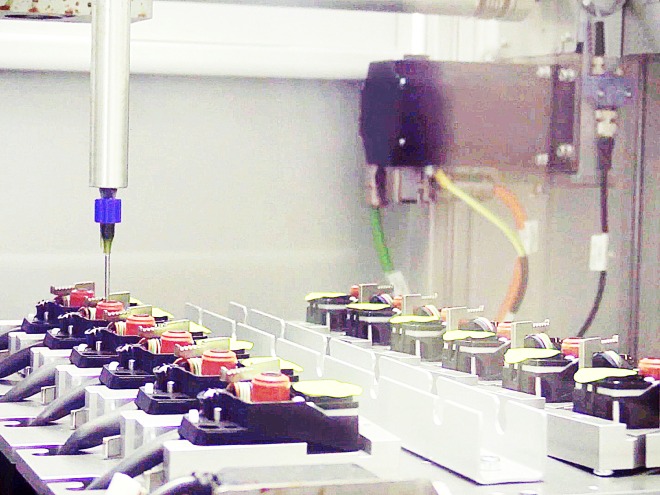

In our in-house validation center we demand a lot from your products.

Here we simulate and test a wide range of loads. This applies to both the hardware and the software of your product. Standardized or self-developed tools, as well as standardized test equipment and processes ensure reliable results.

Our Mission

In our actions, we constantly question ourselves to find clever solutions for access and connectivity, HMI controls and electronic control units to make peoples‘ lifes easier, more comfortable and secure.

(Managing Director Dr.-Ing. Sascha Berger)

experience and competence.

More then 30 years of development and production.

Intelligent, high-quality designed products.

All relevant competencies united.

We are RF specialists.

Stable partnerships ensure complementary know-how.

Contact us

You pose the question, we provide the solution.

Write us using the contact form below or by email.

Project enquiries

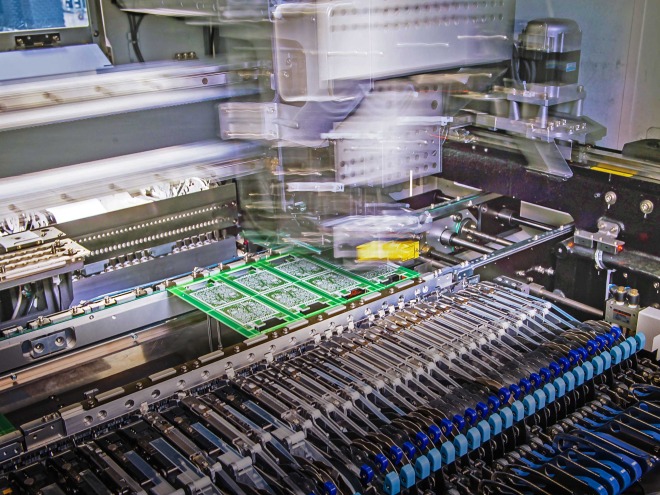

Realization at the highest level.

We work according to the latest standards. IATF, IPC, ISO, FUSI ... - from prototype to series.